About Us

The company was established in 1985 and has expanded its facilities in central India. In addition to manufacturing, the company also produces fine-blanked and machined components for various OE applications.

Milestones

1985

Commencement of Operations (Unit I)

1996

ISO 9002:1994 Certification

2003

QS 9000 Certification

2004

Techno-Sales Collaboration with Seeger-Orbis, Germany

2005

Commencement of Operations (Unit II) TS 16949:2002 Certification

2011

TS 16949:2009 Certification DUNS DSB Registration

2013

ISO 14001 and OHSAS 45001 Certifications

2015

Completion of second shed (Unit II)

2016

IATF 16949:2016 Certification

2019

Commencement of Operations of Wire Division (Unit III)

2023

Green Supplier For MSIL

( VSA Qualified )

2023

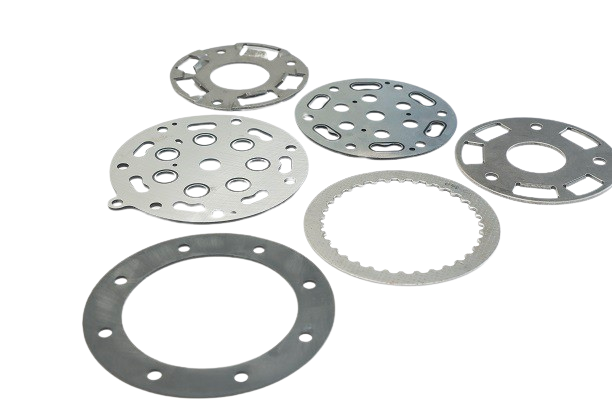

Commencement of operation of fine blanking & machining

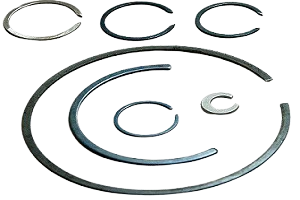

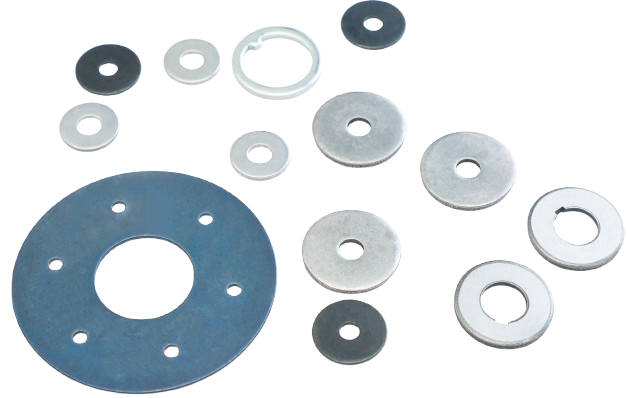

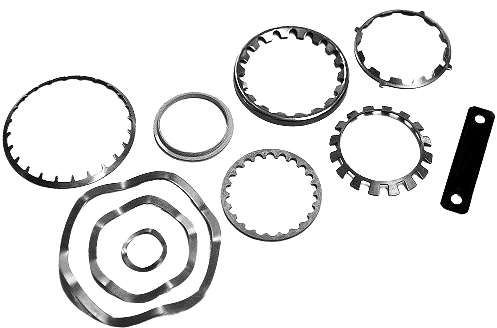

Our Products

Why Star Circlips?

Quality Assurance

Objective : Continuous improvement of processes and products, involving all our workforce, for the overall benefit of our Customers

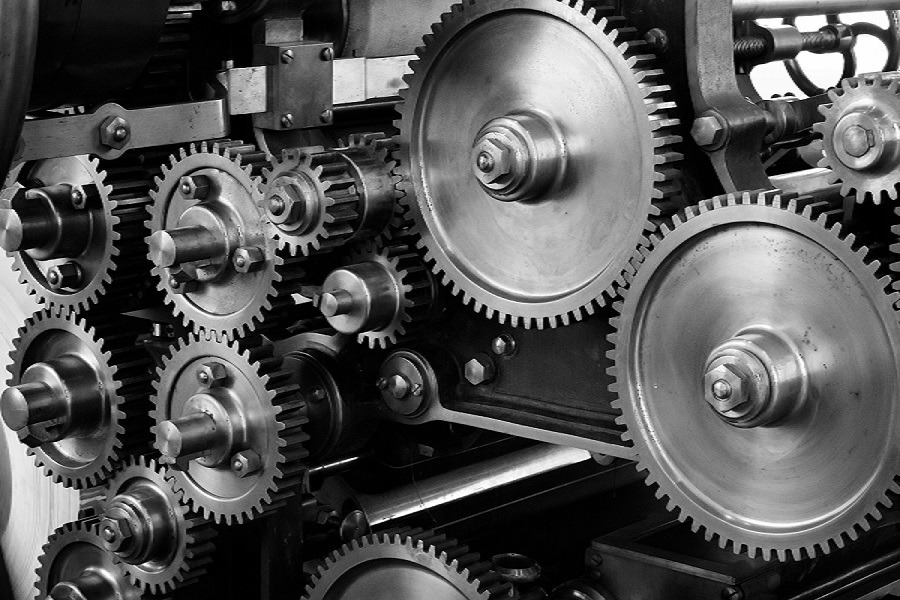

Manufacturing

Star Circlips manufactures components or parts that are unique, customized, or specialized for a particular application, system, or industry

Industries We Serve

Sustainability

Energy

Resource Conservation

-Plastic re-usage and recycling

--Rainwater Harvesting

Customers